High fashion often presents a style that is perhaps best left on the catwalk, but these days some of the more conceptual ideas are presented with the aim of popularising a new way of seeing things.

So when, for its spring/summer (SS)2023 menswear collection, the Spanish brand Loewe recently showed sweatpants, hoodies, coats and shoes sprouting living chia and catswort plants, it wasn’t just a feat of design and engineering – the result of a collaboration with textile designer Paula Escalona – but a hint at future plant-based fashion possibilities.

That’s even if, unsurprisingly, you won’t find Loewe’s green-leaved clothes for sale any time soon. Indeed, Escalona describes her intention as being to get people talking about fashion’s relationship with nature – something at the forefront of sustainable thinking, of course.

The connection between plant-life and fashion specifically is certainly in the air. The use of mushroom-based mycelium to create a vegan alternative to leather – it is already being used to create fully bio-degradable packaging – is increasingly widespread.

And last year, for example, the Royal Horticultural Show in London unveiled designer Lottie Delamain’s Textile Garden: a showcase made up entirely of plants that can be used as a dye or fibre for textile production.

The textile industry is the second largest polluter of water globally – a significant portion of which is caused by the use of synthetic dyes made from toxic petrochemicals that can cause harm to human health and the environment

Plants have provided natural colour in our clothing since textile dying began with the rarity of the plant often being the determining factor in the price of the garment, notably with ‘royal’ purple, black and indigo. Royal purple came from the Phoenician trading city of Tyre, now in modern-day Lebanon, where fabric traders obtained the dye from a small mollusk that was only found in that region.

Dying for Dye

Today the textile industry is the second largest polluter of water globally, a significant portion of which is caused by the use of synthetic dyes made from toxic petrochemicals that can cause harm to our health and the environment. In fact, some 25 per cent of all chemicals produced globally every year are for use in the clothing industry, many of them dyes. The majority of these include heavy metals, the likes of mercury, cobalt, lead, tin, cadmium and chrome that can pollute local water courses.

It is estimated that around 10-15 per cent of all dyes used in textile production are lost during the dyeing process and end up in wastewater as many small-scale factories in textile dependent economies across Asia still lack proper wastewater treatment facilities.

This leads to significant pollution of local waterways and groundwater affecting the lives of those who depend on the water source. The World Bank estimates that around 20 per cent of global industrial water pollution comes from textile dyeing and finishing.

A change of attitude regarding dyeing is needed in the textile and fashion industries, reckons Delamain – a return perhaps to the use of more natural plant-based dyes. The point of her garden, now relocated to Headington School in Oxford, UK, was, says Delamain, to underscore a perhaps forgotten, but very real connection, between plant-life and the clothes we wear.

Other textile futurists are also considering how re-visiting plant-life, and exploring new approaches to it, might play a more practicable part of our wardrobes to come – one perhaps that doesn’t require the careful transportation, transplantation, timing, watering and temperature regulation that Loewe’s show did to look as pristine as it did. Such was the complexity of making plants literally take to fabric.

Plant-Based Fashion Futurists

The complexity of developing plant-based textiles has, to date, typically made for products only commercial at the luxury end of the market. When the Italian luxury goods company Loro Piana launched a €3000 blazer in a limited edition of just 20, each presented in a lacquered box, some might have concluded that it was a victim of its own hype. But, incredibly, the price and presentation may have been justified: after all, these jackets were made from lotus leaves.

On a visit to the shores of Lake Inle in Burma, joint-CEO Pier Luigi Loro Piana had discovered an ancient and little-known handcraft of extracting fibres from lotus leaves and weaving them, extremely delicately, into a silk-like yarn. The process yields very little and must be done within 24 hours of extraction before deterioration sets in. Loro Piana was so impressed, he bought the community’s entire production for the foreseeable future.

Certainly intensely regional, artisanal and cultural methods have long created textiles using plants. Delamain was in part inspired to make her Textile Garden after a trip to Vietnam, where she came across families following a centuries-old practice of growing their own plants to make textiles. She was, she says impressed “by the close proximity between what they grow and what they wear, and how intimately they understood the provenance of their clothes – a far cry from where we are in [developed countries].”

The textile industry uses huge quantities of freshwater – estimates suggest a staggering 20,000 litres are used to produce just one kilogram of cotton

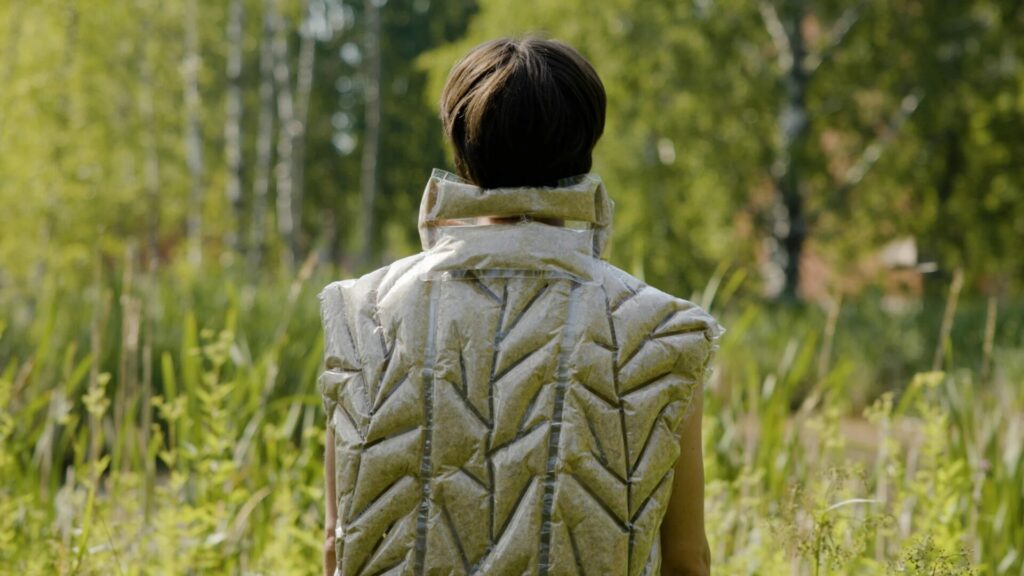

But increasingly textile designers are exploring new, and more widely accessible plant-based textiles. Take for example, Fluff Stuff, a textile filling, for quilted puffa-style clothing, launched last autumn and derived from plants cultivated on rewetted peatlands in Finland, and created by engineer Lukas Schuck and designer Tea Auramo of Helsinki’s Aalto University. Instead of carbon-intensive polyester, or duck-intensive duck down, Fluff Stuff fills garments with the long, cigar-shaped seed beds of broadleaf cattail.

What’s key here is not that this is a more environmentally-sound filling but, claim Auramo and Schuck, that it also absorbs 66 percent less water than down and dries twice as fast. It’s that kind of product improvement that is invariably necessary to encourage consumers to make the switch.

The design team has even created a prototype vacuum-style machine to harvest the cattails from the rewetted peatlands on which they’re grown. This also provides an incentive for those peatlands to stay wet – drained peatlands account for around half of all agricultural emissions in Finland.

And back in 2020 students of London’s Royal College of Art and Imperial College launched a project that created fabrics from plants grown in seawater that could, potentially, be used as an insulating jacket liner, as a faux leather and perhaps for basics like T-shirts. The design team points out that their project also raises awareness of the huge qualities of freshwater that the textiles industry uses, especially in relation to cotton – estimates suggest some 20,000 litres are used to produce just one kilogram of cotton.

Given the pressures on fresh water resources around the world, inevitably some re-thinking of cotton production methods is necessary, meaning that ‘freshwater-free’ is set to become an ethical standard in clothing design as ‘organic’ or ‘carbon neutral’ has become. The students are now planning SaltyCo, a company to commercialise their saltwater-based textiles to produce a cotton/linen-like woven fabric, a non-woven one and a technical stuffing.

That may not generate the column of inches of Loewe and its sprouting clothing, but it would be another small – but arguably much more real – step towards making textiles that bit more sustainable.